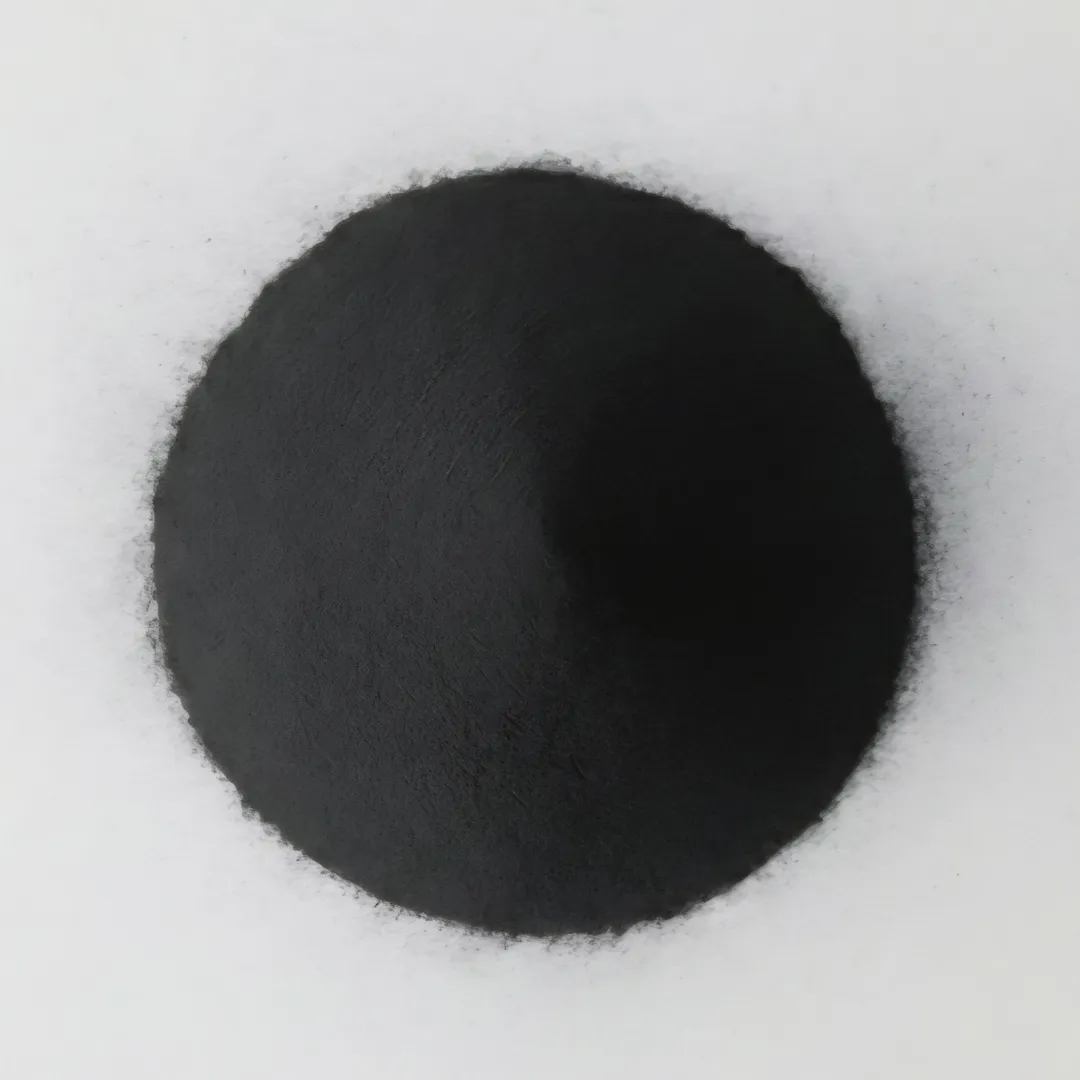

Gilsonite

ارسال رایگان

تحویل اکسپرس و سریع

20 هزار محصول

روش های پرداخت

پشتیبانی 24/7

پشتیبانی نامحدود آنلاین

تحویل 2 روزه

پیگیری سفارشات

| Purity/Grade |

Minimum 98% carbon content (industrial grade); higher purity grades also available |

|---|---|

| Physical form |

Powder; soluble in organic solvents |

| Color |

Black to dark brown |

| Applications |

Oil and gas (drilling fluid additive), asphalt modification, paint and coating production, ink production, foundry |

| Packaging |

25 kg bags, 1000 kg jumbo bags |

| Storage conditions |

Store in a dry, cool, well-ventilated area; temperature 15 to 30 degrees Celsius; avoid heat and humidity. |

| Certificates |

(CoA)؛ مطابق استاندارد API برای کاربردهای حفاری |

Gilsonite

HsCode: 271490

Raeis industrial group is a leading manufacturer and supplier of mineral and inorganic chemical materials used in various industries. Gilsonite is one of the highly utilized and well-known products across industries Raeis industrial group is considered one of the prominent suppliers of this product, with a team of technically proficient experts, prepared to facilitate the export of chemical products and to serve water treatment facilities.

Applications of Gilsonite in Drilling Mud and Its Benefits

Gilsonite is a crude petroleum material with high viscosity and lubricating properties, used as an additive in drilling mud. Optimal use of this material can enhance wellbore performance, reduce drilling hazards, and improve return on investment.

- Applications A) Oil and Gas Drilling

- Improved drilling mud performance in oil and gas wells: Gilsonite increases viscosity and covers the rock surface, helping stabilize the wellbore and minimize fluid loss.

- Challenging formations: In high-pressure environments or with hard formations, Gilsonite reduces contact between the lubricant and the formation, decreasing wear. B) Geothermal Drilling

- Increased well stability: Gilsonite forms a protective layer on the wellbore wall, preventing collapse and fluid loss.

- Control of fluid loss at high temperatures: Gilsonite’s lubricating property helps maintain fluid stability at elevated temperatures and reduces performance decline. C) Exploration Drilling

- Improved sample quality: Gilsonite reduces fluid interference and enhances particle separation.

- More reliable drilling operation data: With greater fluid stability, higher-quality samples can be recovered.

- Benefits of Using Gilsonite A) Reduced operational costs

- By improving drilling mud performance and reducing issues such as sticking and low lubrication, unintended costs decrease and operation time shortens. B) Increased drilling rate

- Lubrication and reduced friction between the wellbore wall and drilling mud accelerate drilling and shorten non-productive time. C) Reduced formation damage

- Controlling fluid loss and forming a protective layer on the formation prevents damage or wear and improves fluid return. D) Environmentally friendly

- Gilsonite is a natural material and, compared to some industrial additives, has fewer environmental impacts, improving environmental sustainability in drilling projects.

- Gilsonite in Asphalt and Road Construction

Gilsonite serves as a supplementary additive in asphalt mixtures and road construction mortars for several key purposes: improving material stability, increasing resistance to thermal shocks, and enhancing wear resistance on high-traffic surfaces. This natural mineral, with a distinctive carbon structure, forms a protective layer on the surface that helps reduce water ingress and improve the durability of asphalt layers.

Key Benefits

- Improved adhesion and stability of asphalt mixes: increases bonding between aggregates and bitumen and enhances resistance to segregation across different temperature levels.

- Increased water and moisture resistance: reduces water penetration into underlying layers and improves bitumen durability against corrosive effects, especially in humid areas or in freeze-thaw cycles.

- Improved thermal stability: better resistance to daily and seasonal temperature changes, extending the life of asphalt layers.

- Reduction of surface cracks and wear-related damage: lowers surface cracking under traffic loads and heat by distributing stresses more evenly within the asphalt layer.

- Improved project execution efficiency: reduces construction defects in both hot and cold mixes, and facilitates spreading and compaction operations.

Practical Applications

- Hot and cold asphalt: as a complementary additive in both hot and cold mixes to improve performance and durability.

- Road surface coatings: creating wear- and skid-resistant layers in conjunction with other resistant additives.

- Modification of existing materials: enhancing the base properties of asphalt by adding Gilsonite to repair and resurfacing mixtures.

- Road construction in dry/humid climates: optimizing moisture characteristics and reducing water seepage through layers.

Execution and Safety Notes

- Appropriate ratio: depending on the mix formulation, the Gilsonite-to-material ratio should be defined to avoid unwanted changes in viscosity and performance.

- Compatibility with bitumen and aggregates: assess compatibility with the specific bitumen and aggregates used in the project to prevent mix inconsistency.

- Environmental and safety requirements: comply with standards for producing and using mineral additives, waste management, and worker safety.

Conclusion

As an efficient additive, Gilsonite can play a key role in improving performance, reducing costs, and mitigating environmental impact in road construction. Given its properties, it is a suitable option for use in various construction operations and can enhance the performance of asphalt mixtures when combined with other additives. If you’d like the tone adjusted (more formal or simpler), a more precise length, or a focus on specific aspects (e.g., economic impact or environmental effects), I can rewrite accordingly.

Description

File type

Download

9 reviews for Gilsonite

There are no reviews yet.